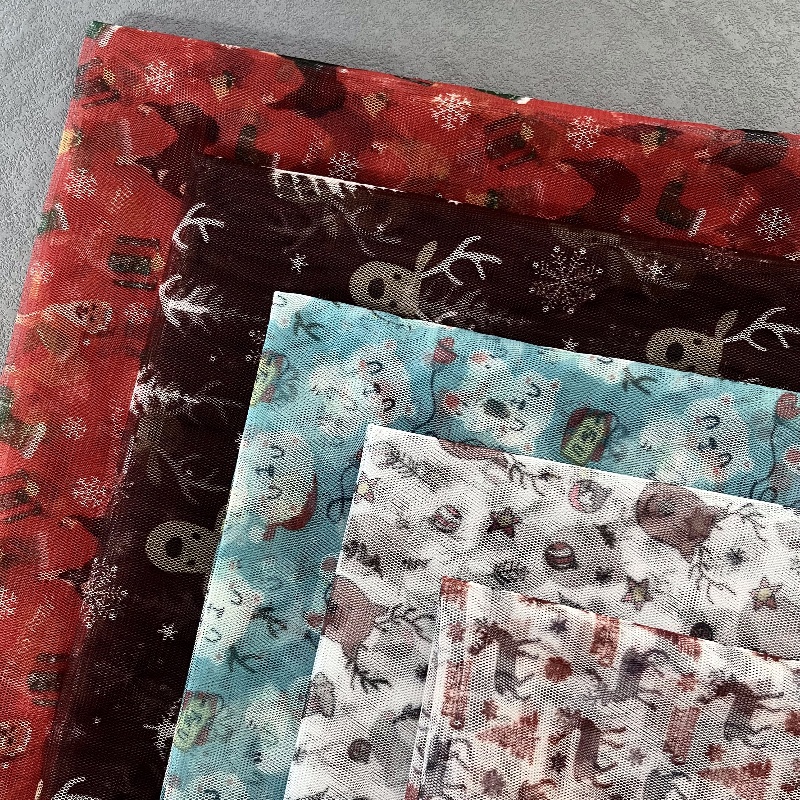

Fluorescent Agent Testing, commonly found in textiles, have raised increasing concern due to their potential health risks. While these agents enhance the visual brightness of fabrics, their inclusion in consumer goods must be carefully monitored to ensure compliance with health and safety standards. This article delves into the reasons for testing fluorescent agents in textiles, outlines the standards and testing methods, and highlights the importance of selecting a reliable testing institution.

The Risks of Fluorescent Agents in Textiles

Fluorescent whitening agents (FWAs) are complex organic compounds that absorb ultraviolet light and emit visible blue light. This property creates a whitening effect that makes fabrics appear cleaner and brighter. However, these agents can pose significant health hazards when used improperly:

- Difficult to Metabolize

When fluorescent agents bind to proteins in the human body, they are challenging to metabolize and eliminate. This prolonged presence can weaken immune responses and impair wound-healing processes. - Toxicity to Vital Organs

Studies have linked fluorescent agents to adverse effects on critical organs, including the liver. This has prompted strict regulation, especially in regions such as Europe and North America, where certain toxic fluorescent agents are explicitly banned. - Environmental and Cumulative Impact

Prolonged exposure to these agents may not only affect individual health but also contribute to environmental pollution, further underlining the need for proper oversight and regulation.

Standards and Detection of Fluorescent Agents

To safeguard consumers’ health and ensure the quality of textiles, specific regulations and standards govern the permissible levels of fluorescent agents in fabrics. Testing can be conducted through the following approaches:

- Third-Party Testing Agencies

Independent organizations can analyze textile samples for fluorescent agent content. Renowned agencies include:- SGS: Global leader in inspection and certification, offering comprehensive testing for physical, chemical, and environmental properties.

- Intertek: Renowned for rigorous testing procedures, from raw material analysis to finished product evaluations.

- National Textile Product Quality Supervision and Inspection Center (China): Specializing in quality and safety testing for a broad range of textile products.

- Certified Labels and Standards

Consumers can look for certification marks such as Oeko-Tex Standard 100 and international eco-labels that ensure compliance with safety and environmental standards. - Domestic and International Standards

Testing protocols include:- HG/T 4433-2012: Standard for fluorescent brightener 5BM.

- FZ/T 01137-2016: Determination of fluorescent brighteners in textiles.

- GB/T 21883-2016: Measurement of fluorescence intensity of fluorescent brighteners.

Choosing the Right Testing Institution

Selecting a qualified and reliable institution is critical for accurate and consistent test results. Here are some tips for choosing a testing agency:

- Verify Accreditation

Ensure that the agency has the necessary qualifications, such as CMA certification (China Metrology Accreditation) or other nationally recognized credentials. - Assess Testing Capabilities

Check the institution’s ability to perform various tests, including type identification, content analysis, biodegradability, and photostability assessments. - Consider Specific Needs

Some textiles, such as baby clothing or functional fabrics, require specialized testing. Select an agency equipped to meet these needs. - Service Efficiency

Choose agencies with proven track records of efficient processing and comprehensive customer service.

Importance of Fluorescent Agent Testing

Testing for fluorescent agents in textiles is not merely a regulatory requirement but a crucial step in protecting consumer health and maintaining industry standards. The process helps:

- Ensure Consumer Safety

By detecting harmful substances, testing reduces the risk of exposure to toxic agents. - Build Market Trust

Compliance with established standards reinforces consumer confidence in textile products. - Promote Sustainable Practices

By adhering to stringent environmental regulations, manufacturers contribute to eco-friendly practices and minimize pollution.

Conclusion

The presence of fluorescent agents in textiles underscores the need for rigorous testing and compliance with health and safety standards. By understanding the risks, adhering to national and international standards, and choosing reliable testing institutions, stakeholders can ensure that textiles remain safe and environmentally responsible. For consumers, verifying certifications and labels is an effective way to confirm product safety. As the textile industry advances, continued emphasis on fluorescent agent testing will be integral to fostering a safer, more sustainable market.