What is Mesh Fabrics?

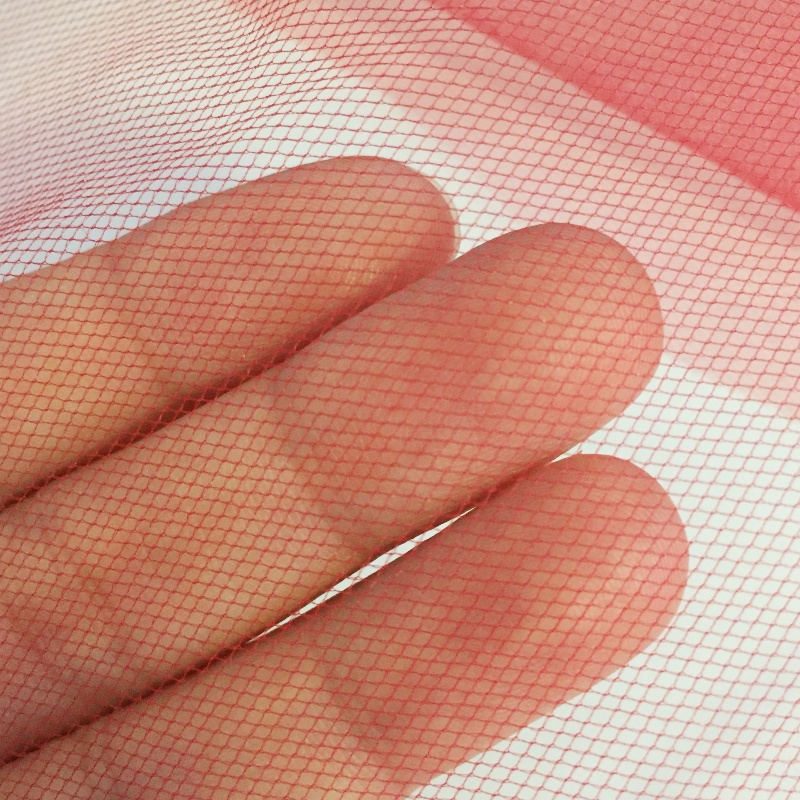

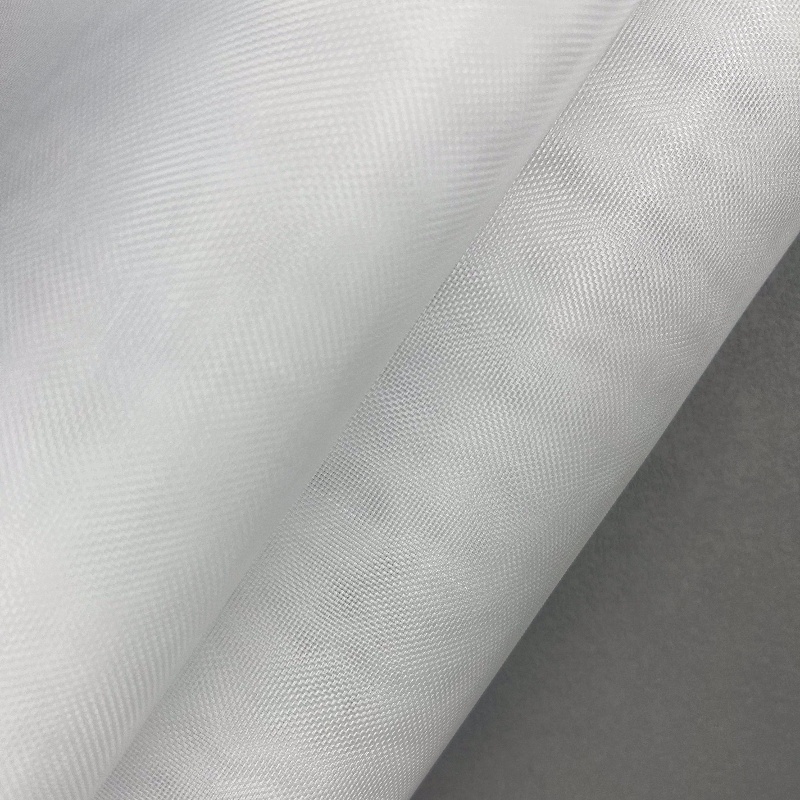

Mesh fabrics refers to any textile with a network-like structure, typically made from materials such as nylon, polyester, or polypropylene. There are several types of mesh fabric including woven mesh, knitted mesh, and non-woven mesh.

Weaving Methods of Mesh Fabric:

- Jacquard or Shed Change Weaving: In this method, three warp threads are grouped together and passed through a single reed, creating small holes in the fabric surface. However, these holes tend to shift, and the structure is unstable, often referred to as “false gauze.”

- Twisted Warp Weaving: This method uses two sets of warp yarns (ground warp and twisted warp), twisted together to form shuttle openings that are interwoven with weft yarns. The twisted warp forms stable holes and is known as “gauze fabric.”

- Plain Weave or Square Weave: By varying the reed density and the weft count, small holes (similar to mesh or screen) are formed.

Types of Mesh Fabric:

- Polypropylene Mesh: Known for its low cost, durability, and easy cleaning, it’s commonly used in applications like fruit and vegetable packaging and geotextiles.

- Nylon Mesh: Lightweight, durable, long-lasting, breathable, and resistant to oil and grease, nylon mesh is widely used in protective gear and filtration.

- Polyester Mesh: This fabric is light, strong, soft, has good water permeability, excellent UV resistance, and high wear resistance. It is suitable for various textile products.

- Steel Mesh: Known for its high strength, rigidity, and corrosion resistance, steel mesh is used in construction, fencing, and industrial applications.

- Asphalt Mesh: Used for reinforcing waterproofing layers.

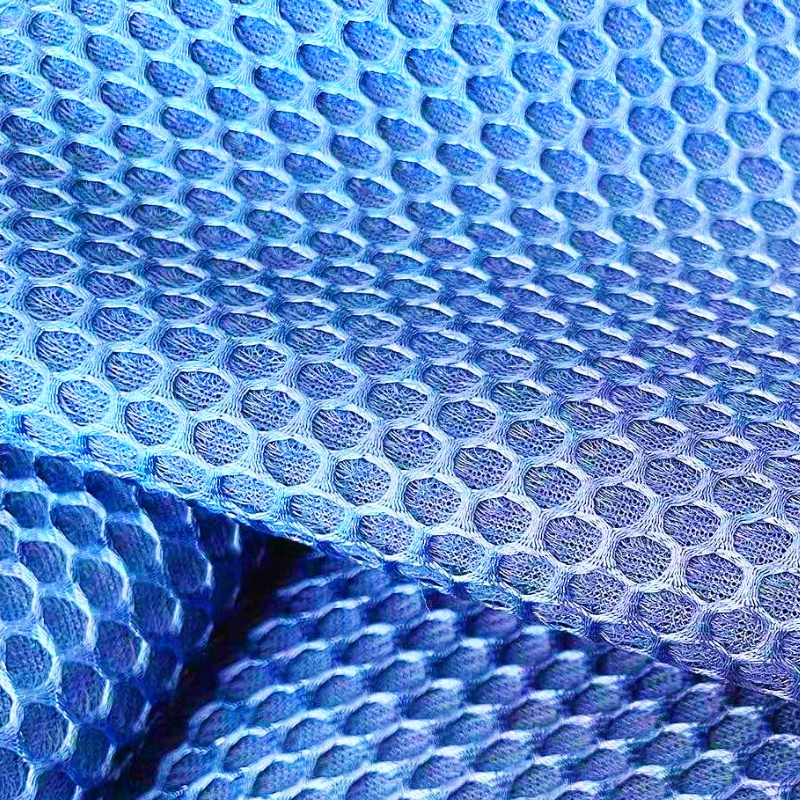

- Warp Knitted Mesh: Includes fabrics like double-eye small pearl mesh, mainly used in garment linings.

- Weft Knitted Mesh: Fabrics like “three-hole one-eye” mesh, widely used in bags, footwear, and daily essentials.

- Large Fishnet Mesh: Commonly used in travel and sports products.

- Single-Eye Mesh: Typically used in daily products and tents.

Applications of Mesh Fabrics in Clothing

Mesh fabric has a wide range of applications in the fashion industry, which include:

- Outdoor Protective Clothing: Mesh composite fabric are commonly used in outdoor gear due to their breathability, windproof, and waterproof qualities. These fabrics offer superior comfort and safety, making them ideal for extreme environments.

- Sports Equipment: Mesh fabric are widely used in sports gear like hiking jackets, ski suits, and wetsuits. These garments require features like windproofing, breathability, water resistance, and mud repellent qualities, all of which are provided by mesh composite fabric. The lightweight, soft nature of mesh also ensures athletes have a comfortable wearing experience.

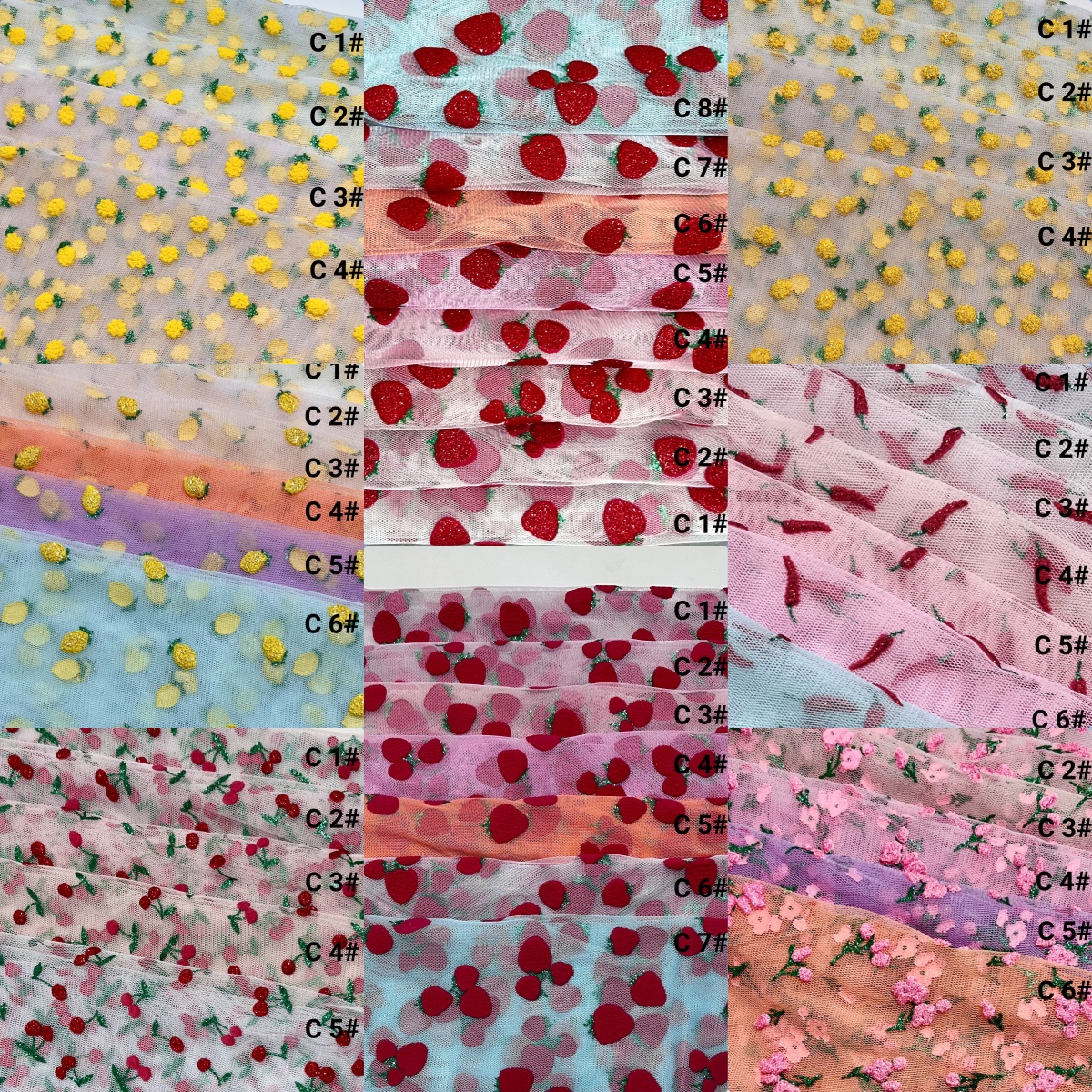

- Fashion Clothing: Mesh embroidered fabric are frequently used in dresses, tops, and other garments to create a dreamy, semi-transparent effect, adding an air of elegance and style. In high-end couture, mesh fabric are often used in evening gowns and formal dresses to enhance the look with a touch of glamour. Additionally, mesh knitted fabric are ideal for sportswear and outdoor apparel due to their breathability, elasticity, and durability, commonly found in running shoes, basketball shoes, and sports vests.

- Accessories: In accessories like hats and bags, mesh embroidered fabric elevate the overall style and quality. They also add elegance to home décor items like curtains and cushions.

Characteristics of Mesh Fabric and Their Role in Fashion Design

- Breathability and Comfort: Mesh fabric are highly breathable, allowing air to circulate, which keeps the surface dry and comfortable, making them ideal for hot or humid conditions.

- Elasticity and Resilience: Mesh’s unique structure is heat-set during production, enabling it to stretch under pressure and return to its original form when the pressure is released. This ensures stability and durability.

- Wear Resistance and Durability: Mesh fabric made from high-performance synthetic fibers are sturdy and can withstand significant tensile and tear forces. The smooth surface is comfortable to wear and resistant to pilling.

- Anti-Mildew and Antibacterial: Many mesh fabric undergo treatment to inhibit mildew and bacteria growth, ensuring cleanliness and hygiene.

- Ease of Cleaning and Quick Drying: Mesh fabric are adaptable to various cleaning methods, dry quickly due to their breathable nature, and are easy to maintain.

- Fashionable Appearance: Mesh fabric come in vibrant, fade-resistant colors with three-dimensional hole patterns. They embody a balance between modern trends and classic styles, making them both visually appealing and functional.

Conclusion

Mesh fabric are versatile, functional, and highly valued in the textile industry for both their practicality and aesthetic appeal. Whether for protective gear, sportswear, fashion items, or accessories, mesh fabric offer unique benefits like breathability, comfort, elasticity, and wear resistance. As mesh fabric continue to evolve, they will remain an essential part of the textile world, offering innovative solutions across various applications.