The Feature of Water-soluble Nonwoven Fabric.

The excellent water solubility, hydrophilicity, and moisture absorption of water-soluble fibers have been applied to various fields and are very promising functional differentiated fibers.

The main feature of the water-soluble fabric is its water solubility, and the fabric can be dissolved in hot water very well. It can be dissolved in high temperature, medium temperature, and low temperature water respectively to meet the different product needs of customers.

The strength and hardness of water-soluble fabric are very good, with excellent impact resistance. Of course, the water-soluble fabric also has excellent weather resistance, even if long-term exposure to the sun, its strength loss is not large.

It can degrade itself in the natural environment, and the bags made of it will not be as indecomposable as plastic bags.

Water-soluble fibers are used for sizing the warp yarns of fabrics, with the advantages of uniform sizing, stable chemical structure, good corrosion resistance, simple and easy process.

Water-soluble PVA fiber has ideal water solubility temperature, strength, and elongation, good acid resistance, alkali resistance, dry heat resistance. Moreover, it is non-toxic after dissolving in water, and the water solution is colorless and transparent, which can be decomposed naturally in a short period of time without any pollution to the environment, and it is a 100% green product.

The Applications of Water-soluble Nonwoven.

The product and its compound products can be used in embroidery, medical treatment, nursing protection, surgery and disease prevention and treatment, home textile field, etc. It can be hydrolyzed and degraded after use, and has extremely broad application prospects.

Medical and sanitary materials made of water-soluble nonwoven fabrics have the characteristics of easy hydrolysis and no pollution. They are commonly used as disposable surgical gowns, caps, bibs, adhesive gauze, surgical dressing materials, medical bed sheets, work clothes, work caps, etc. After disposable use, it is dissolved in hot water at about 90℃.

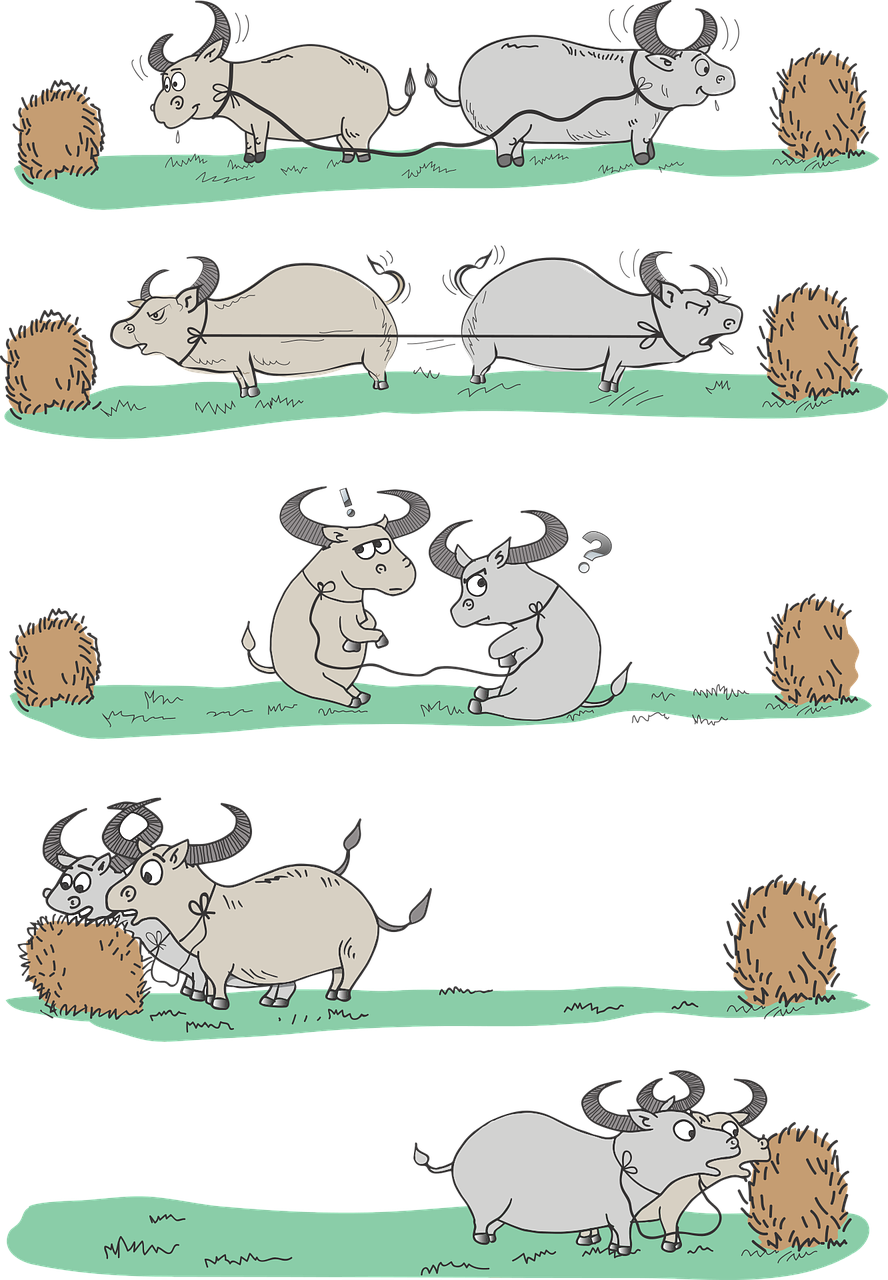

Companion spinning and weaving: water-soluble PVA fiber is used as an intermediate fiber to blend with other fibers, and the water-soluble fiber is dissolved after textile processing to get high-grade textiles, increasing the gap between wool fibers, making wool fabric lighter, softer, more fluffy and warmer.

Water-soluble fiber and cotton, hemp, and other natural fiber blending can change the internal structure of the yarn, increasing the gap between the fibers and capillary pores inside the yarn, thus changing the breathability of the fabric.

Production of microfiber: water-soluble PVA and nylon, polyester, polyethylene, polypropylene and other composite fibers, after stretching treatment, and then wash away the PVA, you can get superfine fibers.

Application in embroidery base fabric: On the base fabric, embroider the desired pattern, then dissolve the PVA component, so that the fabric to obtain a beautiful pattern. The water-soluble nonwoven fabric is embroidered and then the lace is removed, making a breakthrough in the traditional lace manufacturing industry.

Application in the paper industry: water-soluble fibers are used as binders for paper copying to improve the strength and toughness of paper, which greatly improves the fracture and tear strength, folding resistance, and printing surface strength of finished paper.