💧 Spunlace Non-Woven Fabric: The Soft Power Behind So Many Essentials

Let’s talk about something you probably use every day but never think twice about—Spunlace Non-Woven Fabric! Whether it’s in baby wipes, face masks, surgical gowns, or even your home cleaning wipes, this unassuming fabric plays a huge role in our modern lives. And yes—it does a lot more than you’d expect. 👀

🤔 So, What Is Spunlace Fabric?

At its core, Spunlace is made by blasting high-pressure jets of water onto a web of fibers. This entangles the fibers without needing glue or heat, keeping the natural feel of the material while still giving it strength and structure. It’s kind of like nature and technology doing a high-five! 🌿🤝💦

🧵 What’s It Made Of?

This fabric is all about options! Depending on the purpose, it can be made from:

- Natural fibers like cotton, silk, and flax 🌱

- Synthetic fibers like polyester, rayon, and nylon

- Specialty fibers like carbon, metallic, or ultra-fine microfibers for high-tech uses

The blend determines the fabric’s strength, softness, moisture-absorption, and even static resistance. In other words, Spunlace is built to adapt.

💡 Why It’s So Popular

✔️ Super soft and skin-friendly

✔️ Breathable and highly absorbent

✔️ Doesn’t fray or fuzz—hello, clean cuts ✂️

✔️ Feels more like traditional woven fabric

✔️ Can be patterned for a stylish finish

✔️ Strong enough for industrial use, gentle enough for baby wipes

Plus, since it doesn’t need adhesives, it’s also washable and more environmentally conscious 🌎💚.

🏥🧼 Where You’ll Find It

Spunlace non-woven fabric is a quiet superstar in a ton of industries:

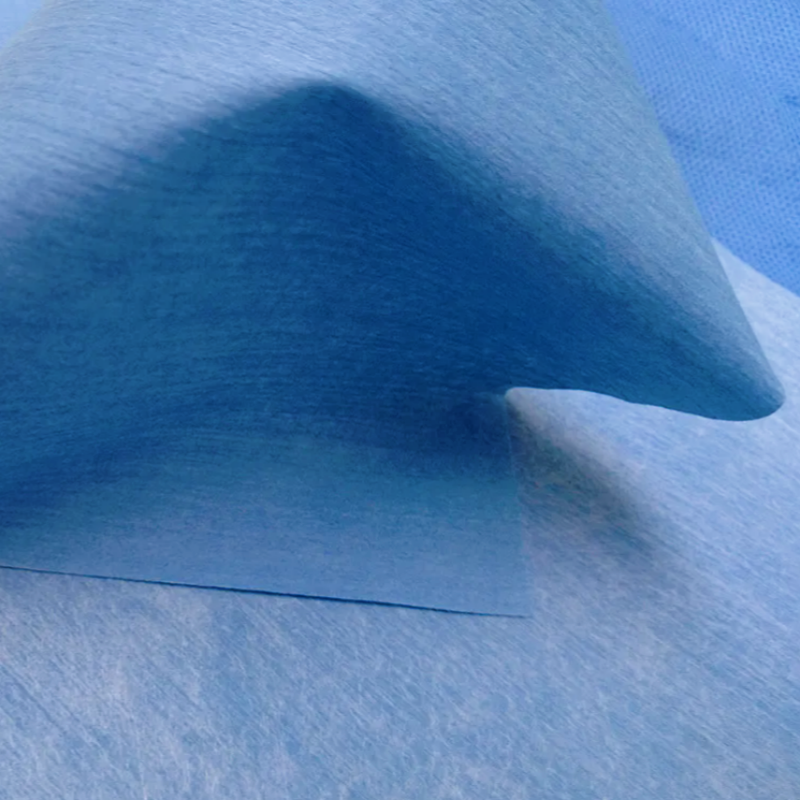

- Medical Use: Surgical gowns, drapes, gauze, dressings, and even face masks

- Hygiene Products: Wet wipes, diapers, sanitary pads, nose masks

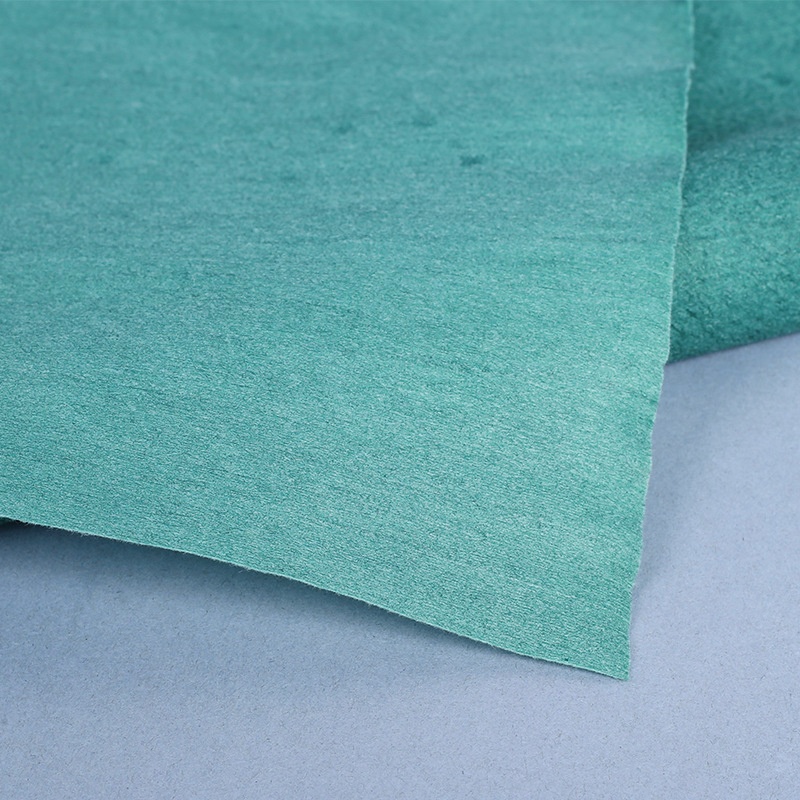

- Household & Industrial Cleaning: Dry/wet wipes, microfiber cloths, paint wipes

- Apparel & Linings: Baby clothes, sportswear, and protective garments

- Decor & Agriculture: Tablecloths, bed sheets, weed-control sheets, insect-proof covers

It’s everywhere—and for good reason! 💥

🔬 Tech Talk: How It’s Made

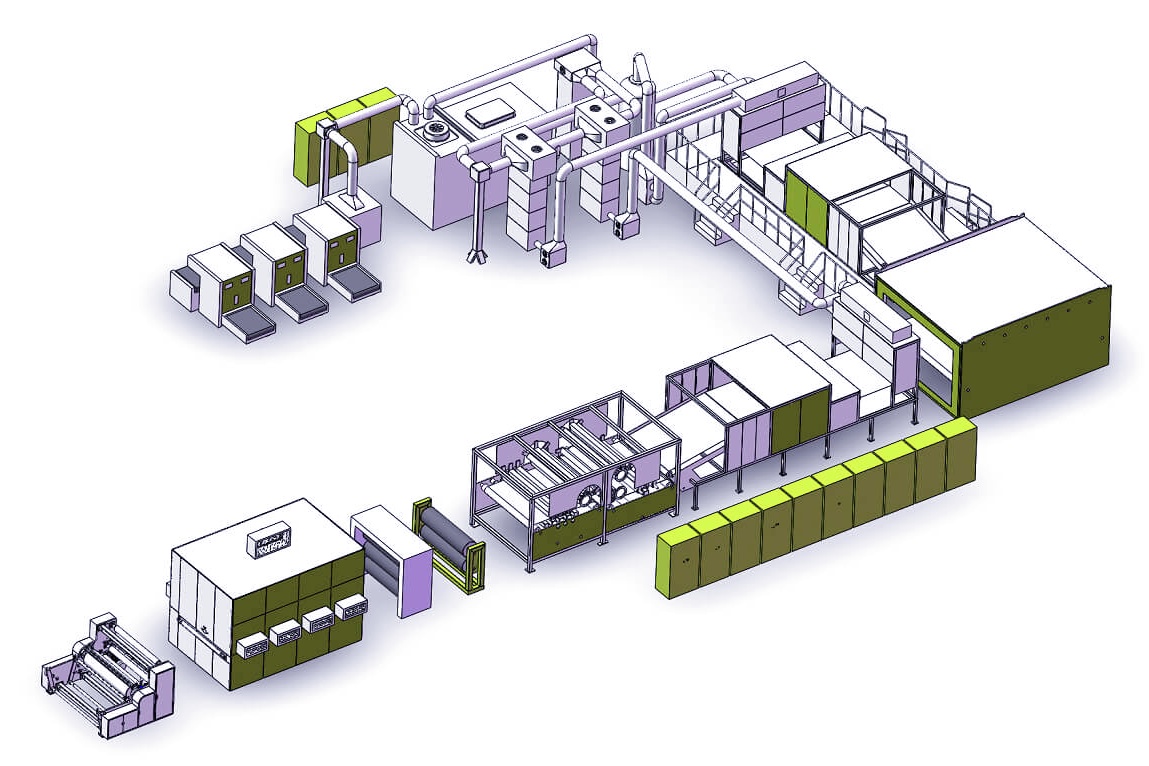

The production of Spunlace involves high-speed machines and precise water technology. The process usually includes:

- Fiber Opening – Loosens the raw fibers

- Carding – Aligns them into a uniform web

- Hydroentangling (aka Water Jetting!) – The magic moment when water binds it all

- Drying & Finishing – Locks in strength and texture

- Rolling & Cutting – For easy transport and use

With more innovation on the horizon—like combining Spunlace with wood pulp or spunbond layers—this fabric is evolving fast to meet even more demands.

📈 Growing Fast in China… and Beyond!

In China, especially in Zhejiang and Jiangsu provinces, Spunlace production is booming. Even during economic slowdowns, new production lines are popping up. Technology is moving toward high-speed, high-quality, and large-scale production, with a growing focus on sustainable methods.

💬 Let’s Chat!

Have you used Spunlace fabric without realizing it? Or maybe you’re in a business where it could be a game-changer? Let us know how you’d use this ultra-versatile fabric—we’d love to hear your ideas! 💬👇

The text is original and the pictures are from the Internet. If there is any infringement, please contact us to delete it. Thank you!