Why Is Tulle So Expensive? Understanding Mesh Fabric Pricing in Fashion & Decor

Unpacking the True Cost of Mesh Fabrics in Today’s Fashion Industry

Tulle—delicate, airy, and ethereal—is a staple in bridalwear, performance fashion, and event décor. But if you’ve ever shopped for mesh fabric and been surprised by the huge range in pricing, you’re not alone.

Let’s dive into the real reasons why tulle (also known as mesh fabric) can be surprisingly expensive—and why sometimes, it’s worth every penny.

🧵 1. Not All Tulle Is Created Equal: Material Quality Matters

The fiber content of your tulle plays a major role in determining price and performance. High-end tulle made from 100% nylon offers:

-

Superior softness

-

Longer lifespan (over 3 years in use)

-

Higher colorfastness and shrink resistance

In contrast, low-cost polyester tulles may feel stiffer, hold dye poorly, or start sagging after just a few washes.

🧪 Example: Tulle used for U.S.-style tutu skirts (often called American glitter tulle) might shift from nylon to polyester to cut costs—but that change impacts both feel and durability.

📏 2. Weaving Density = Durability & Cost

One often-overlooked price factor is mesh density, measured in GSM (grams per square meter). Denser tulles are:

-

Less likely to tear

-

Better at holding embroidery or rhinestones

-

More structured and premium-feeling

💡 Tip: Always ask for GSM specs before buying. Higher GSM = higher durability = higher price.

⚙️ 3. Advanced Manufacturing Techniques Add Value

Modern tulle production goes beyond basic weaving. Today’s designers demand finishes like:

-

Flocking & foil printing

-

Heat transfer graphics

-

Rhinestone application

-

Embroidery or glitter infusion

Each technique adds labor time, material cost, and production complexity, which translates into a higher price tag—but also higher fashion value.

🌍 4. Global Market Forces Affect Tulle Pricing

Just like cotton or silk, mesh fabric pricing fluctuates due to:

-

Global supply & demand

-

Rising electricity and labor costs

-

Seasonal trends (like wedding season)

-

Exchange rate volatility and shipping costs

📈 When demand surges (e.g., before prom or Christmas), tulle prices can spike by up to 30%.

✅ Investing in Quality Mesh: Is It Worth It?

Absolutely. Choosing high-quality tulle means:

-

Longer garment lifespan

-

Less damage during sewing and wear

-

Greater visual impact on stage or in photos

Don’t let lower prices fool you—premium tulle enhances both the look and feel of your designs.

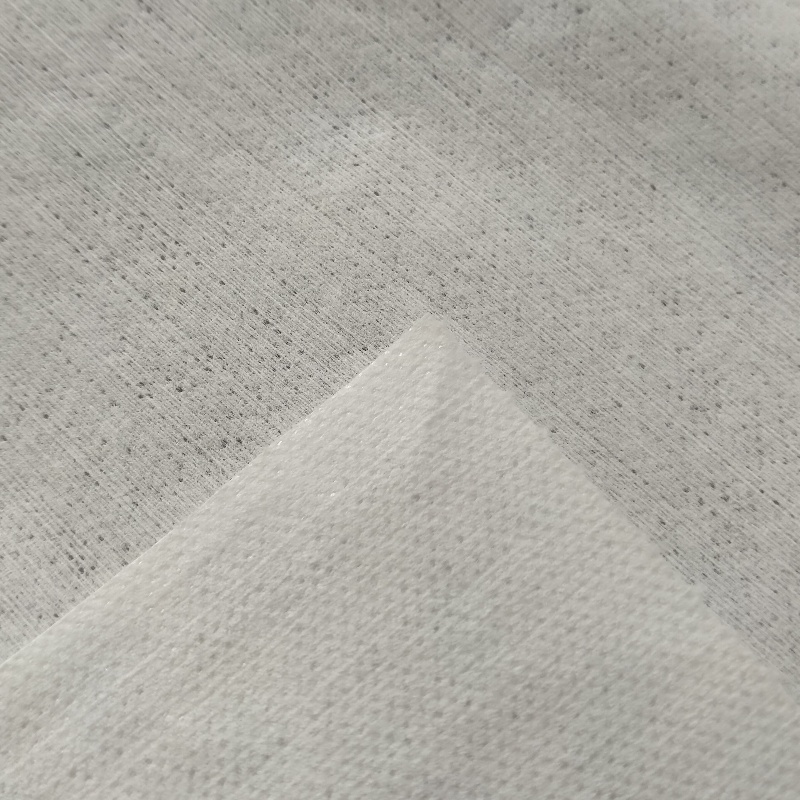

🛍️ Visual Comparison (Optional Graphic Suggestion)

Include a simple side-by-side visual:

| Feature | Low-Grade Tulle | Premium Tulle |

|---|---|---|

| Fiber | Recycled Polyester | Nylon or Nylon/Spandex |

| GSM | ~20–30 GSM | 40–60+ GSM |

| Feel | Stiff | Soft & Smooth |

| Stretch | Minimal | Slight Stretch (if spandex added) |

| Price per yard | $0.50–$1.50 | $3.00–$8.00 |

🙋♀️ FAQ – What Buyers Ask About Tulle

Q: Is polyester tulle always cheaper than nylon tulle?

Yes. Polyester is more affordable but also less durable and comfortable than nylon.

Q: Can I print or decorate on tulle?

Absolutely. Techniques like glitter print, rhinestones, flocking, and foil stamping all work well with the right tulle type.

Q: What’s the best tulle for bridal gowns?

Look for soft nylon tulle with a fine weave (6-sided hexagonal mesh). Embroidery-friendly versions are ideal for veils and skirts.

📣 Call-to-Action

Looking for high-performance tulle with custom finishes like foil, glitter, or embroidery?

👉 Contact us today to request free swatches or explore our mesh fabric catalog.

Let’s bring your creative vision to life—with quality you can see and feel.